How to use De-palletiser

to load sheet metal into cassettes of STACK rack

De-palletiser is a device that makes it easier to handle with a pack of sheet metal during:

1. releasing it from a wooden pallet

2. loading it into a cassette

1. releasing it from a wooden pallet

2. loading it into a cassette

Design

A welded rigid frame with movable pins.

The frame has openings for forks with an inner dimension 170x70 mm.

The standard height of the pins is 400 mm.

The pins can be moved manually to adjust their position to the design of your wooden pallet.

The pins have plastic caps.

The frame has bottom panels to put the pins there.

The frame has openings for forks with an inner dimension 170x70 mm.

The standard height of the pins is 400 mm.

The pins can be moved manually to adjust their position to the design of your wooden pallet.

The pins have plastic caps.

The frame has bottom panels to put the pins there.

Operation method

1. Put a cassette on the de-palletizer frame with a forklift truck or stacker.

The pins should be placed into a correct position to pass between the profiles of the cassette.

The pins should be placed into a correct position to pass between the profiles of the cassette.

2. Put a pack of sheet metal with a wooden pallet on the pins using a forklift truck, stacker or an overhead beam.

3. Cut and remove the metal bands that tie the pack to the wooden pallet. The pallet falls onto the frame. The pack remains on the de-palletizer pins.

4. Lift the pack with a forklift truck, stacker or overhead beam (you can use a lifting beam to take the pack more carefully). Remove the wooden pallet.

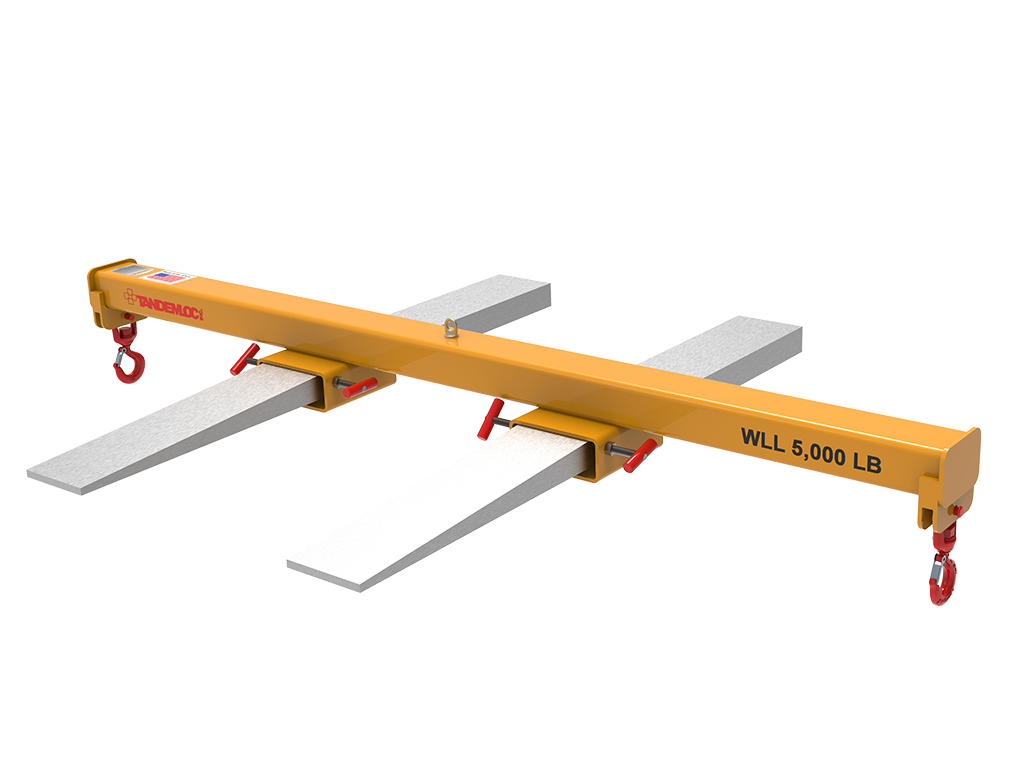

Lifting beam

5. Put back the pack onto the de-palletizer pins.

6. Lift the cassette with a forklift truck or stacker. When lifted over the pins, the pack is loaded into the cassette.

To speed up these operations, you can use two de-palletizers simultaneously:

one to remove the wooden pallets

the other to put the packs into the cassette

one to remove the wooden pallets

the other to put the packs into the cassette

© 2020 Raxmet

ProductS

navigation